For centuries, construction has stayed slow, manual, and expensive. Every house is treated as a one-off project. Meanwhile, industries like automotive and aerospace embraced mass production long ago. Only 14% of firms are using BIM for fabrication and prototyping, showing just how far behind we are. The result is simple: delays, high costs, and homes that fewer people can afford.

Digital fabrication is shifting that reality. Homes can now be designed like products—built faster, with precision, and at a fraction of the cost.

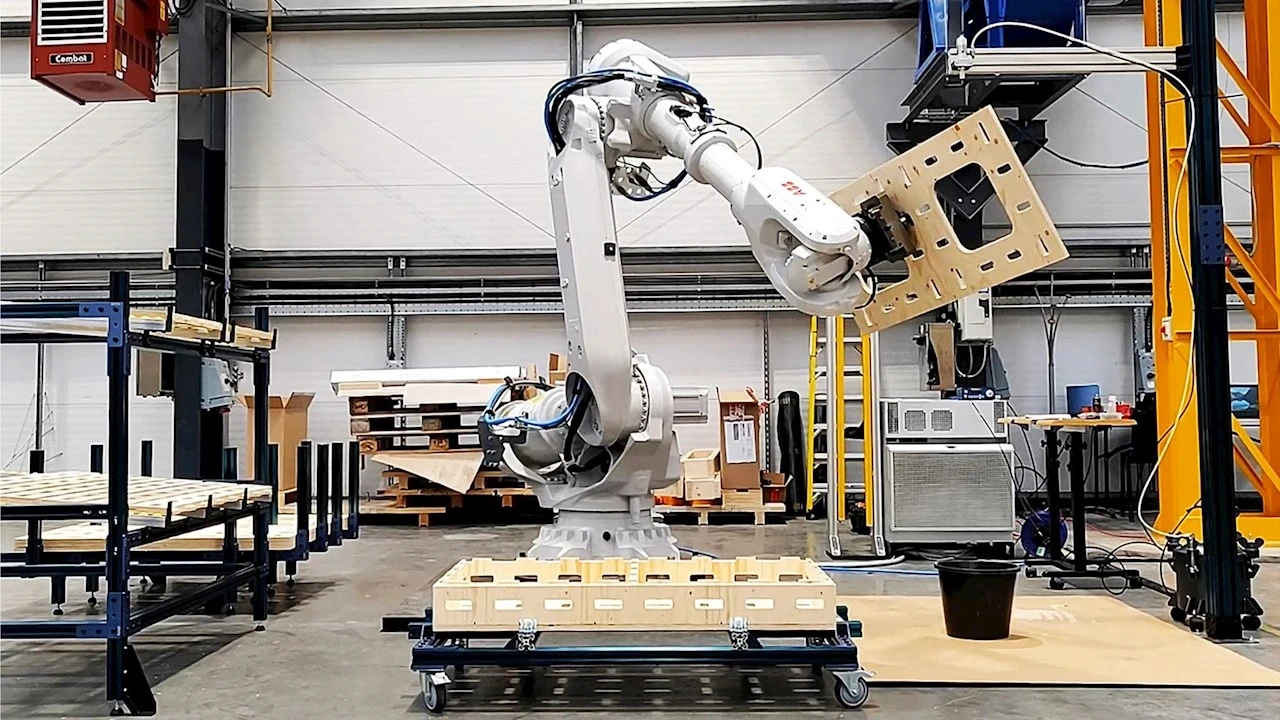

Traditional construction is fragmented. Multiple contractors, unpredictable labor, and material waste pile up. Quality is inconsistent, timelines blow out, and costs rise. Compare this to digital fabrication, where components are manufactured in controlled environments and quickly assembled on site. Machine-readable models feed directly into CNC routers, 3D printers, and robotic arms, cutting errors and keeping design and construction aligned.

The rise of 3D printing shows what’s possible. Entire homes can be printed in days instead of months. The University of Maine’s BioHome3D was created in just 48 hours using bio-based materials. In Texas, the first 3D-printed Starbucks opened. In Europe, couples are already living in printed houses.

Modular construction is another driver. Prefabricated modules slash build times by 30 to 50 percent while reducing reliance on on-site labor. ICON Architecture’s Graphic Lofts project finished months ahead of schedule. Companies like Boxabl are proving foldable homes can scale quickly.

Automation and robotics are the third pillar. Two-thirds of contractors already use robotics, with systems like the Hadrian X laying bricks in hours with near-perfect accuracy. Machines are taking on repetitive work and freeing up skilled labor.

The barriers are real. Many firms don’t have the digital infrastructure or workforce training. BIM and fabrication software don’t always integrate seamlessly. Building codes are slow to adapt, often excluding new materials like 3D-printed concrete or bio-resins. But the direction is clear. Architects will have to design for machines as much as for people, using computational tools and fabrication-driven workflows.

The future of construction is a hybrid model where prefabrication, robotics, and AI complement traditional methods. Homes produced with the precision of an assembly line will make high-quality housing more accessible. Adoption won’t happen overnight, but the only way forward is to bridge the tech, training, and regulatory gaps.

Digital fabrication is not just an upgrade. It’s the shift that can finally make housing affordable, efficient, and scalable.